Processed potatoes are widely demanded food items in homes and restaurants across the world. It is for this reason that they are preferred for many foods, particularly anytime foods. But how are these delicious products manufactured? People can read this guide to learn how to produce frozen potato products—from market size estimation, to potatoes farming and manufacturing.

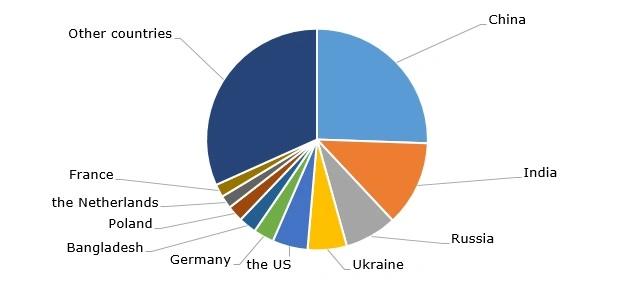

As per FAOSTAT database, Potatoes are amongst the leading food crops in the globe whose production is estimated at over 383 million metric tons per year. Potato growers are China, India, Russia, USA and Ukraine though China retains the largest share of production. Potatoes are grown in both the tropical and the temperate regions, making them a very important crop around the globe.

China: The biggest producer of potatoes, it grows more than 93 million metric tons every year.

India: One of the world's largest producers of potatoes with production at over 60 million metric tons.

Russia & Ukraine: Main actors in the European potato market.

United States: A leading global producer of potatoes, targeting specific types that are ideal for the frozen products sector.

For example, potatoes are produced to cater for the growing world population and increasing markets for convenience foods and increased innovation in production techniques, mechanization of farming and development of higher yielding and quality seed varieties has boosted production.

The process of frozen potato products starts with sourcing potatoes that have been correctly sourced and harvested. Farmers raised starchy types like Russet or Idaho, as those are used for the best frying. The type of potatoes that are used to make frozen products is normally Russet type which is characterized by high starch and close when cooked. After that the potatoes are moved to processors where they go through several processes as a way of producing the frozen products.

Potatoes are washed with brushing rollers which quite possibly can remove dirt and scorches without causing any harm to the skin of potatoes. This is usually done using high-pressure water spray or mechanical cleaning tools or scrubbers. At this stage, any potatoes which are bad or have any damaged potatoes removed at this stage to ensure the final product's quality. After washing, they may be peeled using special machines to remove the outer layer but in such a way that minimal produce is wasted and they end up with a smooth surface.

After peeling, potatoes are again sorted by hand to remove any spoiled or bad pieces of potatoes even though they try to counter check these during the initial washing process. These quality control checks are very vital as they mean that only the best potatoes get to the next level.

After that, the potatoes are washed and peeled before being chopped into equal sizes of strips. The potatoes are sorted based on size where small potatoes are used in preparing tater tots, while the larger ones are used in fries and wedges. Another piece of equipment is cutting machines that produce uniform thickness, necessary for equal browning. French fries' basic thickness looks to be about 1/4 inch.

One of the crucial facts for the perfect crispy fry, cut fries are needed to be soaked in cold water for some time. This soaking maintains that excess starch that is present on the surface of fries does not get deposited again when frying in order to make them gummy but instead makes the fries harder and crispier.

Blanching is another important stage, when soaked fries are subjected to boiling in hot water at a temperature of 70-95 C. This process serves multiple purposes:

It deactivates enzymes, which are responsible for discoloration of food in the process of preparation and cooking.

It assists in reducing the crispiness of the fries slightly.

It also reduces the amounts of sugars on the surface so that it may not undergo severe browning once fried.

After blanching, fries are immediately cooled down so as to prevent further cooking from taking place.

The potatoes are then dried to remove additional moisture after the blanching process has taken place. This is very important for the final product texture. It is also important to get rid of too much moisture because it makes the potatoes soggy and don’t become crisp when cooked.

These potatoes are then dried after which they are cooled to enhance their freezing. Cooling allows the cooking process to stop and with the freezing process the texture of the potatoes does not change.

Next you have what is called par-frying. French fries are frying in hot oil at approximately 175-185 degrees celsius for a short amount of time, which is two minutes for example. This initial frying forms the outside crunchy layer and deep frying prepares the inside for a soft and fluffy layer. Frozen par-fried fries may be held and cooked later at home or in restaurants where they are a popular order.

They usually have the appearance of extra oil coating the fries after going through par-frying. If there is any excess of this oil they move through a turning belt which has small holes where oil is allowed to drain out while the fries remain intact.

The next step is quick freezing, which is imperative for maintaining the quality of the product and avoiding the formation of freezer burn. The fries are transferred to a quick freezing unit in which the temperature dips below -36 degrees C within a few minutes. It also ensures that ice crystals do not penetrate cells of the potato, which hampers the texture when they are cooked later.

After being fried the fries are conveyed to the freezing line and then transferred to the automatic packing line. Here, they are measured and packed in bags or boxes depending on the size and type and prepared for distribution. The packaging process is important because it shields the product from coming into contact with air and moisture – both of which degrade quality.

Frozen potato products include fries, wedges, hash browns, tater tots, among others; they have been widely accepted in the domestic and international markets, fast foods and food services. The global market of frozen potato products has been consistently growing because of the consumers’ demand for convenience food products and ready-to-cook foods.

Market Value: The frozen potato products market size is projected to reach USD 26.9 billion by 2028 from USD 20.2 billion in 2022, at a CAGR of 4.3% during the same years.

Leading Regions: The key markets that consume the frozen potato products are the North America, Europe and the Asia Pacific with North American being the largest market attributed to fast foods chains and retail uses. Europe is an equally large market, especially in France, Britain and Belgium where fries are a cultural favorite.

Key Products: Most of the fries are the straight-cut fries and the crinkle cut fries; tater tots, Hash browns and wedges.

Frozen potato products are potatoes that have been harvested and turned into a crispy snack through a careful process to ensure they are quality, tasty, and easy to prepare. Each step such as harvesting, sorting, blanching, freezing and packaging has therefore been developed in a way that ensures the best quality produce reaches the consumers every time. As consumer demand for frozen potatoes increases globally, new variants of the product for home cooking and food service continue to flood the market.

Chillfill Foods supplier of top-quality frozen potato products provides an array of products to meet all consumer needs. Whether you're enjoying fries, wedges, or tater tots, you can trust that each product has been carefully crafted for the perfect crunch and flavor.